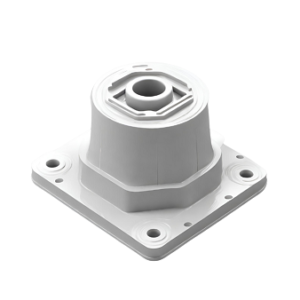

In the world of engineering and industrial machinery, the battle against vibration and noise control is a constant challenge. Vibrations, whether originating from internal sources like motors and engines or external factors such as seismic activity, can lead to inefficiencies, accelerated wear and tear, and compromised precision in machinery. To combat these issues, engineers have developed a key solution: Anti-Vibration Mounts (AVM). These ingenious devices play a crucial role in stabilizing machinery and ensuring optimal performance across a diverse range of applications and industries.

Functions of Anti-Vibration Mounts:

1. Vibration Isolation:

The primary function of AVM is to isolate machinery from external vibrations or dampen internal vibrations. They act as shock absorbers, preventing the transmission of vibrations from the source to the surrounding environment or adjacent machinery and or equipment. This isolation is vital for maintaining the stability and integrity of sensitive equipment, reducing noise levels, and improving overall operational efficiency.

2. Resonance Control:

Anti-vibration mounts are designed to minimize resonance, which occurs when the natural frequency of a system matches the frequency of external vibrations. Resonance can lead to excessive movement and structural damage. By introducing damping mechanisms, anti-vibration mounts disrupt resonance patterns, preventing the amplification of vibrations and safeguarding machinery from potential harm

3. Load Distribution:

In addition to vibration isolation, AVMs support to distribute loads evenly across the mounting points. By distributing the weight of the machinery effectively, these mounts help prevent localized stress concentrations and prolong the service life of both the equipment and the supporting structure. This function is particularly crucial in heavy-duty applications where uneven loading could lead to premature failure.

4. Alignment Correction:

Machinery often experiences misalignment due to various factors such as thermal expansion, structural settling, or manufacturing tolerances. AVMs with adjustable features can compensate for minor misalignments, ensuring proper alignment of components and reducing the risk of mechanical issues arising from misaligned machinery.

Major Applications of Anti-Vibration Mounts:

1. Industrial Machinery:

AVMs find extensive use in industrial machinery across diverse sectors such as manufacturing, power generation, automotive, aerospace, and construction. They are employed in equipment ranging from large compressors, pumps, gearboxes, engines and generators to precision instruments like CNC machines and laboratory equipment.

2. Transportation Vehicles/Vessels:

AVMs play a crucial role in enhancing the ride comfort and stability of transportation vehicles, including automobiles, trains, ships, and aircraft. They isolate the cabin or passenger compartment from engine vibrations, road or rail irregularities, and aerodynamic forces, contributing to a smoother and quieter travel experience.

3. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems rely on AVMs to minimize noise and vibration transmission. These mounts support components such as compressors, condensers, and fans, ensuring smooth operation and occupant comfort in residential, commercial, and industrial buildings.

4. Electronics and Sensitive Instruments:

Sensitive electronic equipment, such as semiconductor manufacturing machinery, medical imaging devices, and laboratory instruments, requires precise vibration control to maintain accuracy and reliability. AVMs provide the necessary stability and protection against external disturbances, ensuring consistent performance in critical applications.

5. Construction and Infrastructure:

In construction and civil engineering projects, anti-vibration mounts are utilized to mitigate the effects of ground vibrations, seismic activity, and machinery-induced oscillations. They support heavy equipment such as pile drivers, cranes, and vibratory compactors, reducing the risk of structural damage and disturbance to nearby structures or sensitive environments.

METAL Mobility operate in multiple markets and industry aim to provide the best bespoke anti vibration solution working with reputable makers across the globe for any industry.

In conclusion, anti-vibration mounts or AVMs, often called Mounts serve as indispensable components in diverse industrial, commercial, and technological applications, offering crucial functions such as vibration isolation, resonance control, load distribution, and alignment correction. By effectively managing vibrations and ensuring machinery stability, these mounts contribute to safer, quieter, and more efficient operations across various sectors, ultimately enhancing productivity and equipment longevity.

Email: sales@statusmobility.com

Tags: Anti-Vibration Mounts Explained, Vibration Isolation Mounts UAE, Functions of Anti-Vibration Mounts, Marine Engine Mounts Middle East, Industrial Anti-Vibration Mounts Dubai, Anti-Vibration Solutions for Machinery, Shock Absorbing Mounts for Equipment, Rubber Mounts for Vibration Control, Anti-Vibration Mount Applications, Engine Vibration Dampers UAE, Anti-Vibration Mounts for Generators, Machine Mounting Systems Middle East, Noise and Vibration Control Dubai, Anti-Vibration Pads for Industrial Use, Vibration Dampening Mounts UAE, Vulkan mounts in Dubai, Rubber Design Mounts Stock in UAE, Spring Mount Dealer, Engine Mounts Supplier in Dubai, Gearbox Mounts Solutions