A Practical Engineering View for Equipment Owners & Maintenance Teams

In heavy industrial environments, Cardan shaft failures are often treated as product problems. In reality, most premature failures are caused by engineering and application-related issues, not by the shaft itself.

Replacing a failed Cardan shaft without understanding why it failed usually leads to repeat breakdowns, increased maintenance cost, and unplanned downtime.

This article explains the real causes of Cardan shaft failures in steel plants, cement plants, mining operations, power generation facilities, and other heavy-duty applications — and what should be done differently.

The Real Cost of a Cardan Shaft Failure

In heavy industry, a failed driveline component is rarely an isolated issue. It often results in:

- Production stoppage

- Damage to connected equipment (gearboxes, bearings, couplings)

- Emergency maintenance and logistics cost

- Safety risks during sudden failure

- Reduced confidence in the entire drivetrain system

Yet, the most common response is simply:

“Replace the shaft with the same or cheaper one.”

This approach almost always fails.

Common Causes of Premature Cardan Shaft Failure

Misalignment is the number one reason Cardan shafts fail early.

In real installations:

- Angular misalignment is higher than design assumptions

- Parallel offset is ignored

- Thermal expansion is not considered

- Equipment settles over time

Even high-quality Cardan shafts will fail prematurely if operating beyond allowable joint angles.

Important:

Laser alignment alone does not solve all driveline misalignment issues — shaft geometry and joint configuration must also be correct.

Many shafts are selected based on:

- Nominal torque only

- Catalog values

- Previous installation history

What is often ignored:

- Peak torque and shock loads

- Start-up and braking conditions

- Load fluctuations

- Safety margins for continuous duty

An undersized shaft may survive briefly, but fatigue damage begins early and failure becomes inevitable.

Applications such as:

- Rolling mills

- Crushers

- Conveyors with heavy starts

- Mining and bulk handling systems

experience sudden torque spikes far above average operating values.

If these transient loads are not considered during selection, the Cardan shaft becomes the weakest link in the drivetrain.

Using:

- Single joint instead of double joint

- Incorrect phasing

- Wrong shaft length

can introduce:

- Speed fluctuations

- Vibration

- Accelerated wear of joints and bearings

These issues often appear as “mysterious vibration” before eventual failure.

Low-cost or unknown-origin Cardan shafts may look identical externally, but often suffer from:

- Inferior material quality

- Poor heat treatment

- Inconsistent bearing tolerances

- Inadequate lubrication sealing

In heavy-duty applications, these weaknesses are exposed very quickly.

One of the most expensive mistakes is:

Replacing a failed Cardan shaft without investigating the application.

If the original failure mechanism is not addressed, even the best replacement shaft will fail again.

Why “Cheaper Replacement” Rarely Solves the Problem

Price-driven replacement decisions often ignore:

- Lifecycle cost

- Downtime impact

- Risk to adjacent equipment

In many industrial cases, the cost of one unplanned shutdown is higher than the price difference between a properly engineered solution and a cheaper alternative.

The Correct Engineering Approach

To prevent repeated Cardan shaft failures, a proper evaluation should include:

- Operating and peak torque assessment

- Duty cycle and start/stop frequency

- Angular and parallel misalignment measurement

- Shaft length and joint configuration review

- Environmental conditions (heat, dust, moisture)

- Installation and maintenance practices

This approach focuses on system reliability, not just component replacement.

When to Seek Engineering Support

You should consider a detailed driveline review if you experience:

- Repeated shaft failures within short intervals

- Excessive vibration or noise

- Visible joint overheating or grease leakage

- Unexpected wear of gearboxes or bearings

- Increased maintenance frequency

These symptoms usually indicate system-level issues, not just a faulty shaft.

Final Thought

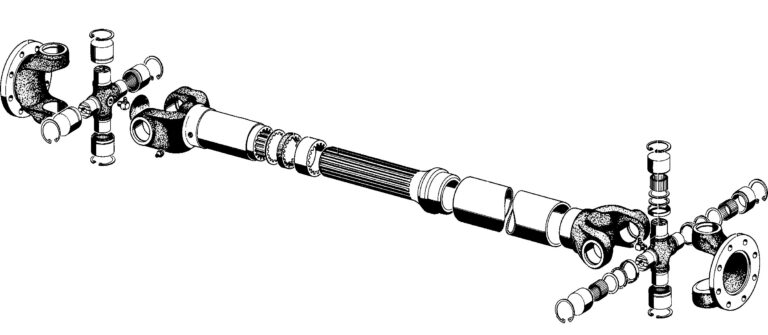

Cardan shafts are critical power transmission components in heavy industry — but they only perform as well as the engineering decisions behind them.

Preventing premature failure is not about choosing the strongest shaft on paper; it is about choosing the right shaft configuration for the real operating conditions.

Let’s Review Your Application

If your operation is facing repeated Cardan shaft failures or unexplained drivetrain issues, a proper application review can prevent future breakdowns.

Our experts can help: